STRUCTURED SEMI RIGID PET SHEET

Recyclable Eco-friendly Sheet for Thermoforming & Packaging

EXPET STRUCTURED SEMI RIGID PETSHEET

PETSheet are a structured clear semi rigid sheet manufactured by the extrusion processing of Polyethlene Terephthalate (PET), a recyclable eco-friendly polymer. PETSheet have sparkling clarity and gloss, exceptional mechanical properties and good thermoforming characteristics, making them the ideal material for rigid packaging applications.

EXPET is a range of high performance PET Sheet manufactured by Interplex India from carefully selected inputs, to exacting standards based on our superior technical capability, professional and systematic approach to manufacturing and continuous research and innovation.

EXPET is manufactured on state of the art imported co-extrusion plant, utilizing the Company’s long experience since 1989 in the field of specialized extrusion. Interplex’s manufacturing facility has BRC Certification for Food Grade and full ISO Certifications.

EXPET has extremely good thickness tolerance, very high uniformity and low crystallinity and excellent transparency.

EXPET GRADES

APET

APETsheet is extruded from virgin PET polymer. APET Sheet has the highest levels of clarity and gloss and mechanical properties.

RPET

RPET sheet is extruded from a blend of virgin PET polymer and recycled PET. RPET sheet additionally has lower carbon footprint and lower cost with the use of recycled inputs.

GAG

GAG sheet is a 3 layer sheet extruded with PET polymer in the centre and PETG polymer in the outer layers. GAG sheet has added properties of better sealing (equivalent to PVC)and superior gloss and forming characteristics.

CHARACTERISTICS OF EXPET

- Sparkling clarity and gloss

- Very good impact strength (down to -20°C)

- High flexural modulus permitting downgauging

- High resistance to cracking and whitening

- Excellent forming characteristics without need for drying

- Faster forming cycle times due to higher thermal density

- Safe for food and drug contact

- Gamma and ETO sterlizable

- Good gas barrier properties

- Good chemical resistance

- Neutral smell and good aroma/flavor protection

- Non toxic and environmentally friendly polymer

APPLICATIONS

Blister and Display Packing

- CONSUMER& OTHER GENERALITEMS- toothbrushes, shaving blades, battery cells, etc.

- POINT OFPURCHASE DISPLAY- electrical, electronics, tools, toys, stationery, apparels, etc.

- FABRICATED BOXES- Clear and printed boxes for gift items, hosiery, hardware, etc.

Functional Packaging

- TECHNICAL- Packaging and handling of electronic components

- PHARMACEUTICALS& MEDICAL- tablets, disposables, medical devices, etc.

Thermoformed Containers and Trays

- FASTFOOD & BEVERAGE / CARRYHOME – beverage glasses, packs for bakery, deserts, salad, etc.

- RETAIL FOODS & CONFECTIONERY – chocolate & biscuit trays, nuts, dried fruit, packed mithai, icecream / dairy produce cups

- FARM PRODUCE – clamshell and tray for fruit, vegetables, herbs, eggs, etc.

SPECIFICATIONS

| Thickness range | 0.23 to 0.80 mm |

| Thickness tolerance | +/-5% (max) |

| Width | 250 – 1100 mm |

| Roll core | ID 76 mm (standard) |

- EXPET Sheet can be offered with enhanced properties for specialized applications according to customers requirements

- EXPET Sheet is manufactured in rolls but can be offered in cut sheets for fabricated and printed box packing applications.

TYPICAL PROPERTIES

| PROPERTY | UNIT | METHOD | APET | RPET | GAG |

|---|---|---|---|---|---|

| Density | gms/cc | D792 | >1.33 - 1.35 | >1.33 - 1.35 | >1.31- 1.32 |

| Tensile Strength at Yield | MPa | D882 | >50 | >45 | >50 |

| Light Transmission | % | D1003 | >89 | >87 | >89 |

| Water Vapour Transmission | gms/mm/M/24hrs | F1249 | 6.0 | 6.0 | 6.0 |

| Oxygen Transmission | gms/mm/M/24hrs | D3985 | <28 | <28 | <28 |

COMPANY BACKGROUND

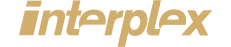

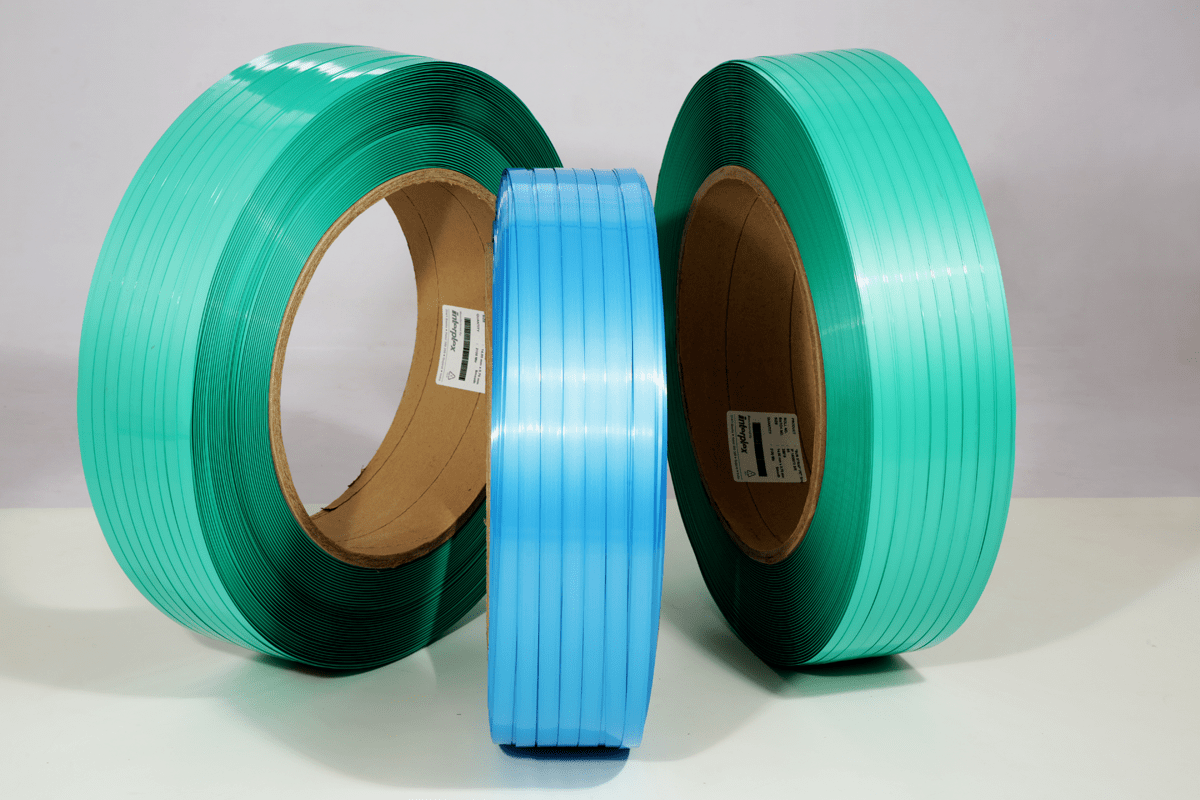

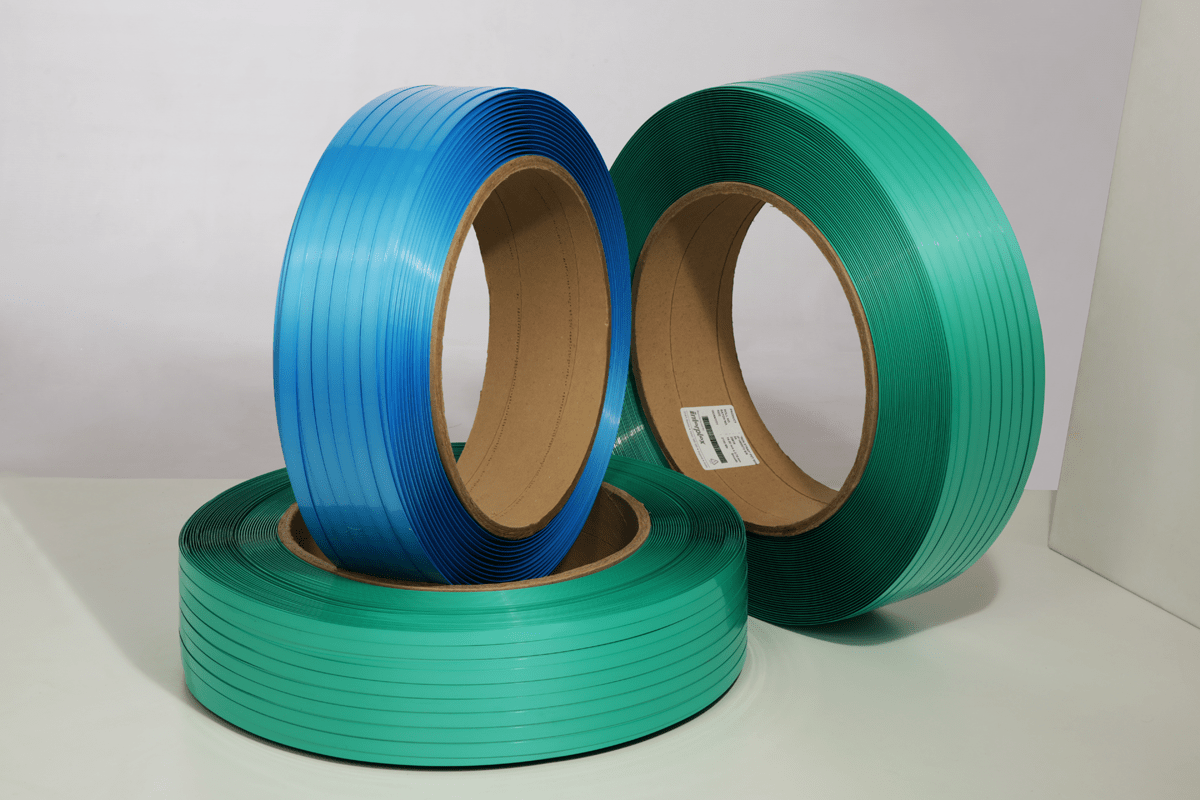

Interplex is a pioneering multi-product company focused on serving markets requiring specialized polymer products for demanding applications. Interplex product range includes Cellulose Acetate Granules for specialized injection moulding applications such as tool handles and high end combs, Multilayer Cellulose Acetate Sheets for manufacturing Spectacle Frames, High Tensile PET Straps, Coextruded Multilayer PET Sheets for the packaging sector and Rigid Thermoformed Containers from PETand other polymers. Interplex has a modern plant near Vadodara with dedicated production lines incorporating state-of-the art processing equipments from Europe and the USA.

Interplex has been promoted in 1989 by Sunil H. Patel (MBA Chicago Booth, AB Harvard USA, OS Eton College UK) and Dr. Hiru N. Patel (PhD Imperial College Lond), one of pioneers of the Plastics Industry in India, Founder President of the Indian Plastics Institute, Past Chairman of Plexconcil, Founding Member of Governing Council CIPETMadras, M.D of Bakelite Hylam and Director of Union Carbide India (Retd.).