HIGH TENSILE PET STRAP

Recyclable Eco-friendly Strap for Critical Load Securement

SUNSTRAP HIGH TENSILE PETSTRAPS

PETStraps are a high tensile polymer strap manufactured by the extrusion and subsequent stretching process from Polyethlene Terephthalate (PET), a recyclable eco-friendlypolymer. Due to their significantly superior characteristics, PETStraps are internationally recognized as a preferred replacement to Steel Straps in many load securement packaging applications. PETStraps are better able to absorb high shock in handling and transportation of the load, can keep load secured more effectively, and have greater elasticity, which is a critical advantage in compensating for tension losses.

Sunstrap is a range of High Tensile PETStrap manufactured by Interplex India from carefully selected inputs, to exacting standards based on our superior technical capability, professional and systematic approach to manufacturing and continuous research and innovation.

Sunstrap is manufactured on state of the art European plant, utilizing the Company’s long experience since 1989 in the field of specialized extrusion. Interplex’s manufacturing facility has full ISOCertifications as well as BISCertification for PETStrap.

Sunstrap has excellent and consistent tensile and break strength and is ideal for the most demanding applications. The customer can trust Sunstrap to provide dependable performance under critical load conditions and at the same time be assured of the most cost efficient solution for the specific load securing application.

SUNSTRAP GRADES

HT GRADE

HT Grade has a tensile 2 strength of 38 – 40 kg/mm and is used in most general high tensile manual strapping applications.

EHT GRADE

EHT Grade has an enhanced tensile 2 strength of 41-43 kg/mm and enhanced properties for more demanding manual strapping as well as some general auto strapping applications.

UHT GRADE

UHT Grade has the highest tensile strength of 46 48 kg/mm achieved by the use of selected inputs. It used in applications requiring ultra high tensile strength and load retention for applications requiring lower strap size for practical reasons and more critical auto strapping applications.

CHARACTERISTICS OF SUNSTRAP

- High retaining strength and controlled elongation due to unique properties of PET which provide excellent resistance to burst

- Excellent retained tension over long period of time, as well as when load is subject to movement and vibration during transportation, or when load is subject to dimensional changes after securing due to settling, such as in baling application

- High shock reserve allowing load to be safely secured under dynamic conditions when load shifts during transportation

- Resistant to rusting allowing strap to be placed directly on product without causing staining or contamination of product

- No sharp edges making it easier and safer to handle, avoiding risk of injuries to operator due to snapback when tensioning and avoiding damage to secured load due to edge cutting

- Lighter weight than steel allowing for easier handling during strapping operations and storage

- Superior weather resistance allowing secured load to be stored in the open

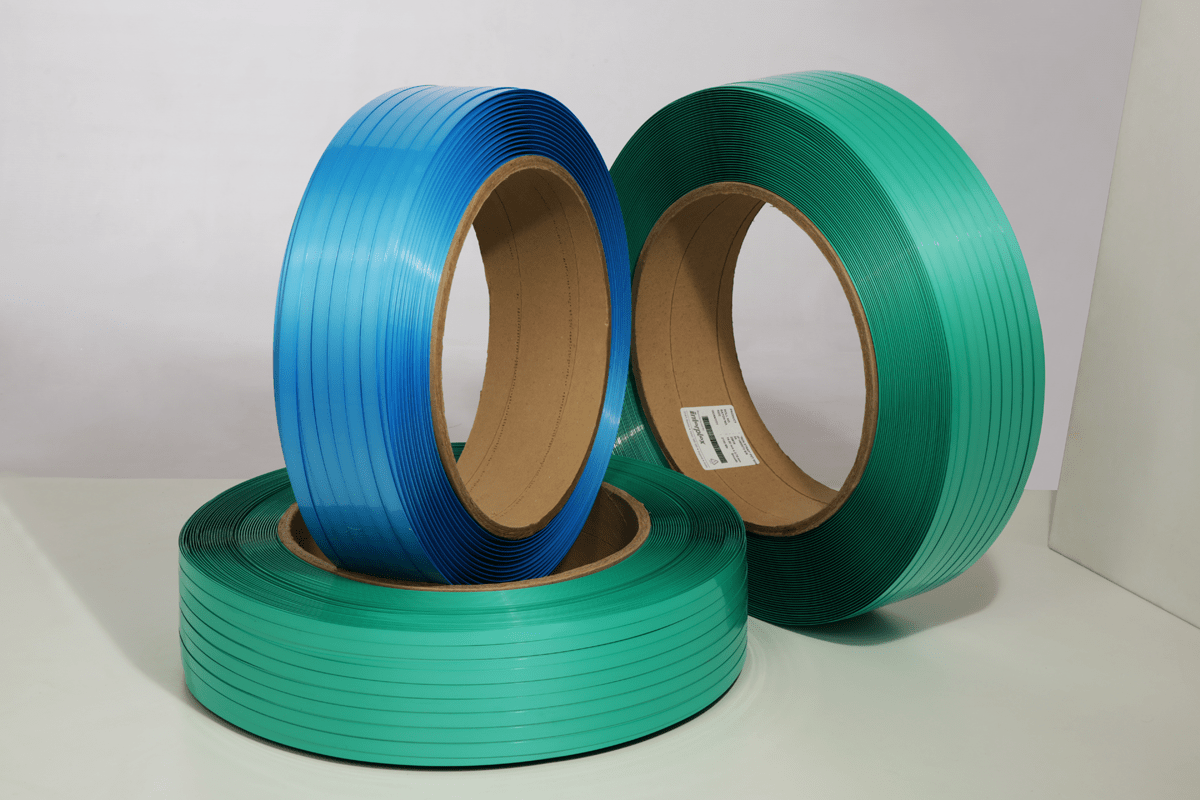

- Easy to seal with special Tools allowing ease of application

- Eco-friendly making it easily recyclable

- More economical than steel strap

APPLICATIONS

Baling of natural fibres such as Cotton, Jute & Coir; Synthetic Fibres; FIBC, Items such as woollen blankets, cloth, etc. which have to be compressed for economical transportation

Bundling of Wood & Timber; Extruded Sections such as Aluminum, Copper, etc.; Non-ferrous Ingots; Paper, Cardboard, Glass, Ceramic and Stone tiles

Load Securementof Paper, Glass, Forgings, Palletization of heavy loads, Crates, Metal Coils, Metal Pipes, Bars and Wires, Coiled Plastic Pipes and Conduits

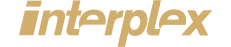

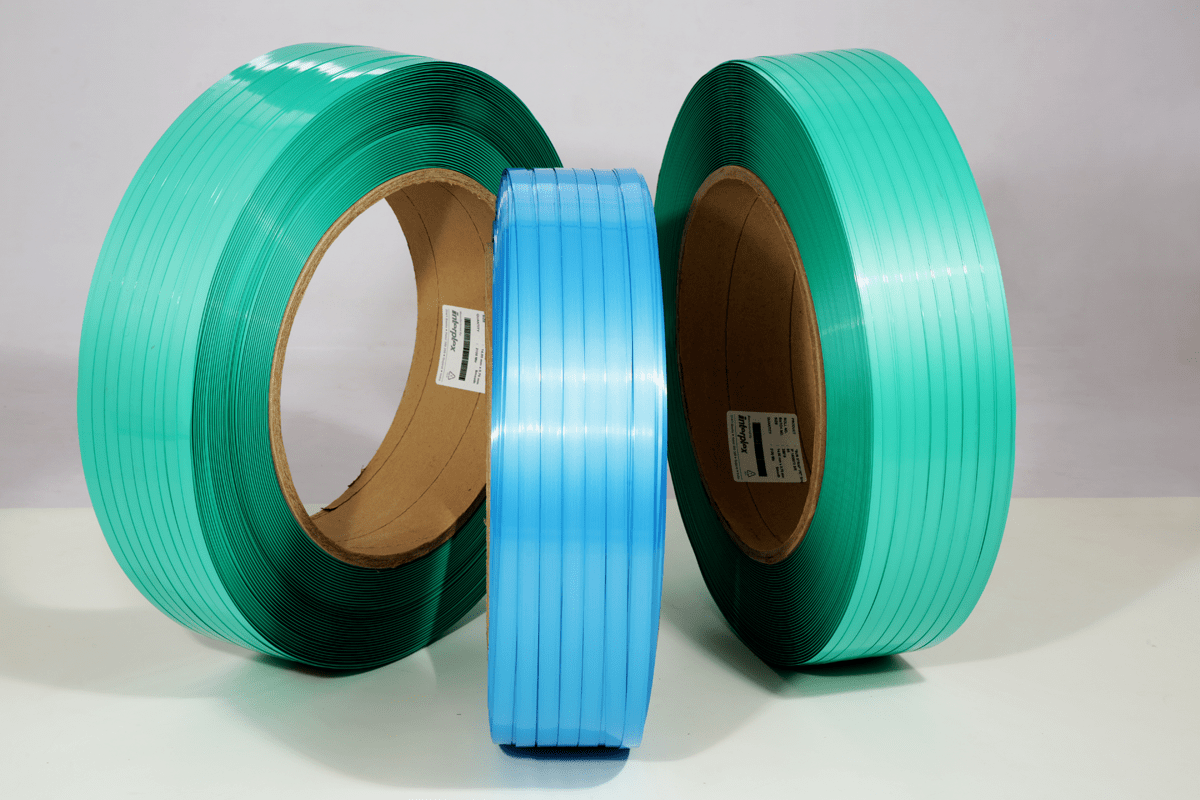

SPECIFICATIONS

| Width | 9 - 32 mm |

| Thickness | k 0.5 - 1.4 mm |

| Colour | Green (standard)/Blue/Blackn |

| Roll Core ID | 402 mm (standard) |

| Roll width | 160 mm (standard) |

TYPICAL PROPERTIES

| PROPERTY | UNIT | METHOD | HT GRADE | EHT GRADE | UHT GRADE |

|---|---|---|---|---|---|

| Tensile Strength | kg/mm | ASTM D638 | 38 - 40 | 41 - 43 | 46 - 48 |

| Elongation (standard) | % | ASTM D638 | 10 - 14 | 10 - 14 | 10 - 14 |

| Density | gm | ASTM D792 | 1.34 | 1.34 | 1.35 |

COMPANY BACKGROUND

Interplex is a pioneering multi-product company focused on serving markets requiring specialized polymer products for demanding applications. Interplex product range includes High tensile PET Straps, Coextruded Multilayer PETSheets for the packaging sector, Rigid Thermoformed Containers from PETand other polymers, Cellulose Acetate Granules for specialized injection moulding applications such as tool handles and high end combs & Multilayer Cellulose Acetate Sheets for manufacturing Spectacle Frames. Interplex has a modern plant near Vadodara with dedicated production lines incorporating state-of-the-art processing equipments from Europe and the USA.

Interplex has been promoted in 1989 by Sunil H. Patel (MBA Chicago Booth, AB Harvard USA, OS Eton College UK) and Dr. Hiru N. Patel (PhD Imperial College Lond), one of pioneers of the Plastics Industry in India, Founder President of the Indian Plastics Institute, Past Chairman of Plexconcil, Founding Member of Governing Council CIPETMadras, M.D of Bakelite

Hylam and Director of Union Carbide India (Retd.).